June 10, 2025 The photography exhibition titled “Saline di Volterra, a Presidential Inauguration (1959)” was…

In late October 2022, the Ministry of Environment and Energy Security allocated 1 billion euros to promote research, development, and innovation in the field of industrial processes. This funding aims to develop initiatives for the use of hydrogen in industrial sectors that rely on methane as a source of thermal energy, while also supporting the production of electrolytic hydrogen from renewable energy sources. The declared goal of this significant initiative is to facilitate the introduction of hydrogen in industrial processes, to decarbonize sectors known as “hard-to-abate,” such as the highly polluting and challenging-to-convert chemical sector.

Esseco Industrial is one of the few national chemical realities that can be considered environmentally sustainable, as it uses renewable energies (primarily hydroelectric and solar) for over 51% of its electrical consumption (data from the first half of 2023). Through its operating companies—Altair Chemical at the Saline di Volterra and Pieve Vergonte sites, and Esseco—the company has long been engaged in a process of rapid transition towards renewable energy sources and is currently developing several project proposals for investments.

It is noteworthy that in 2022, at the Pieve Vergonte production site, the percentage of renewable electrical energy used in the production cycle exceeded 66% on an annual basis.

The company is not new to such endeavors: at Saline di Volterra (PI), Altair Chemical already recovers hydrogen from the electrolysis of brine (saltwater) for steam generation, without any harmful emissions, replacing natural gas (methane CH4), which otherwise produces CO2 in the combustion process. For this purpose, a bi-fuel steam generator has been built capable of operating on hydrogen, methane, or a mix of the two, in a fully automated manner, depending on the instantaneous availability of hydrogen from electrolysis. The modulation occurs automatically, based on the available hydrogen, to maximize its reuse.

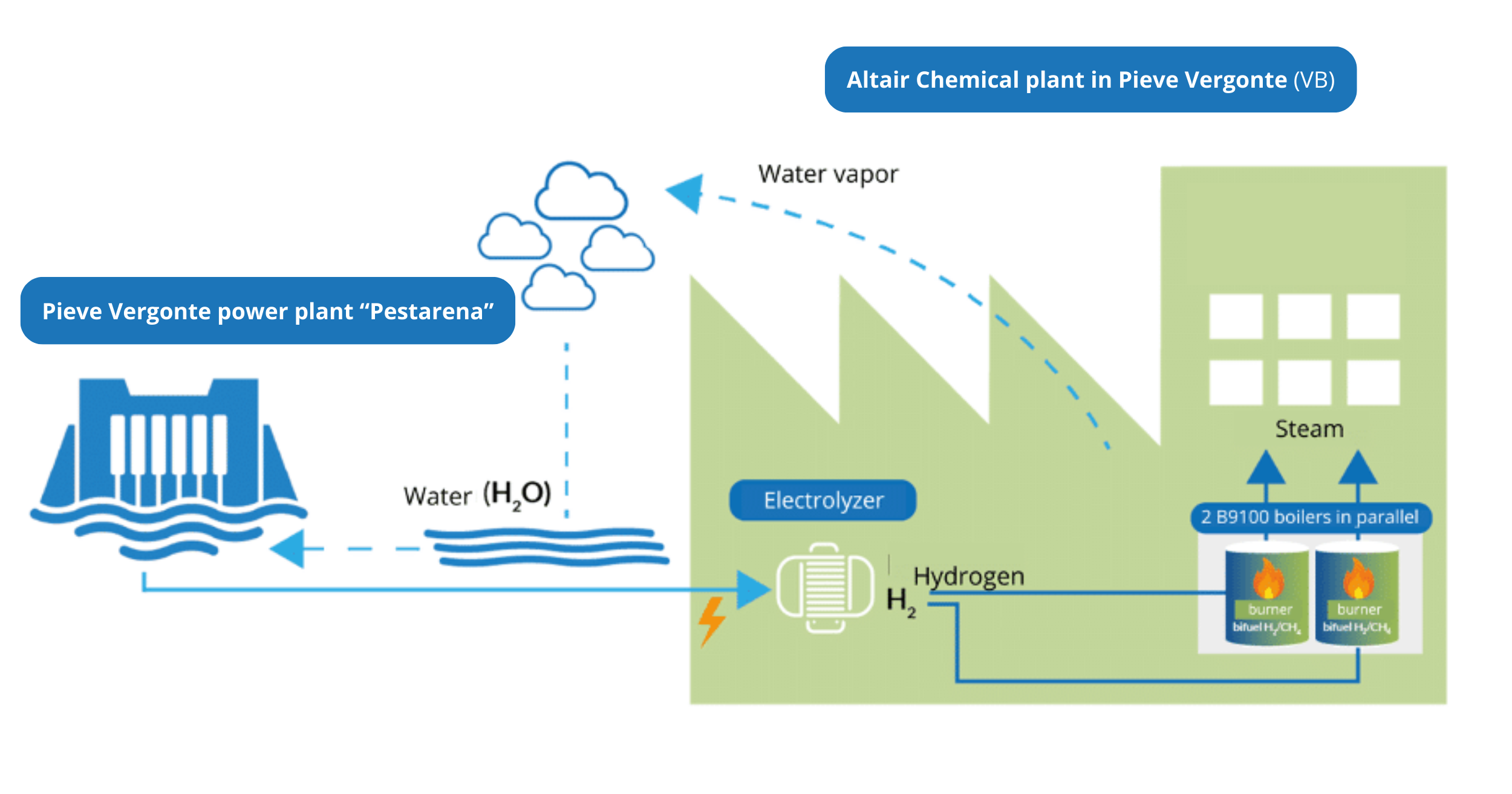

Also, at Pieve Vergonte (VB), Altair Chemical produces hydrogen from the electrolysis of brine, and the residue from its use for the production of hydrochloric acid is used to reduce methane consumption for steam generation serving the distillation column.

The new IdroHydro project might come to fruition at Pieve, should the application submitted to the “Hard-to-Abate” call be accepted. This involves the construction of a new hydroelectric plant capable of producing over 20,000 MWh of green energy annually. Of these, just 600 MWh/year will be used for the normal functions of the facility as they are produced at a lower power. The vast majority, in fact, will be used to power a 6 MW electrolyzer with a productivity of 1.190 million Nm3/h (Normal Cubic Metres Per Hour) of hydrogen at full load (359 t/year), which will be used in two boilers currently operating at Pieve that would be converted from methane-only to bi-fuel (methane, hydrogen, or a mix of the two).

Pairing hydrogen production with renewable energy sources such as hydroelectricity will allow for much higher productivity. To achieve the same results through other green sources, for example, about 20 MW of power from photovoltaics would have been needed. Instead, the IdroHydro project allows for the exploitation of the entire day, thus ensuring greater operation in service of the electrolysis plant. With this setup, it will save over 1.2 million Sm3/h (Standard Cubic Metres Per Hour) of methane per year, equivalent to about 24% of the total methane used.

The IdroHydro project for the production of hydrogen from a renewable source was conceived in full alignment with the goals of the “Hard-to-Abate” call by the Ministry of Environment and Energy Security. The planned investment is approximately 27 million euros, mostly split between the construction of the new hydroelectric plant and the new electrolyzer, with just 0.6 million euros for the bi-fuel boilers.

While awaiting the assessments of the proposing authorities, we hope that this great opportunity, linked to the PNRR, can soon become a new reality capable of combining energy benefits with environmental advantages.